CSN Precision Engineering, Neath Abbey Road, Neath, West Glamorgan SA10 7BR.

Telephone: 01639 644362 Fax: 01639 638596

VAT Reg. No. GB 422 7823 57 BS EN ISO Reg. No. GB 4260 © CSN Precision Engineering

The majority of CSN's clients have been customers for many years. They feel comfortable in the knowledge that they have a partner who will provide them with quality tools and provide sound technical back up.

CSN has been engaged in special simultaneous projects with their Trade Customer Design Engineers, Machine Tool Builders & the End User.

The Company has provided general emergency toolroom cover for companies & engaged in maintenance during shutdown periods.

In addition to manufacturing core product the company also provides subcontract services for :- CNC turning, 3,4 & 5 axis CNC milling general milling, surface grinding, universal grinding, wire eroding, spark eroding, tool balancing and black oxide finishing.

General Production & Machining

As a result of providing customers with tools to produce components, the company has diversified into production work & general machining. Customers have been faced with problems of coping with small batch sizes outside their usual remit, prototype batches that interfere with production runs & components beyond the capability.

The diverse & comprehensive machining capability includes CNC Turning with both chucking & barfeed capacity, CNC 3, 4 & 3+2 Milling, Wire & EDM Eroding and various manual turning milling & grinding capacity.

In addition to small batch production the company also manufactures Jigs, fixtures, gauge fixtures & components for machines.

The company adopts a positive attitude of 'If it is within capability & capacity' it will be undertaken.

PLANT & EQUIPMENT

The company has invested in support software & specific equipment designed to meet the needs of their main market sector.

Custom Business Software

The company utilizes software which has been 'Taylor Made' for the business. They are able to monitor from the enquiry stage right through to eventual archive. The system supports computerize estimating linked to auto email quotation. Orders are back linked to the quotation which produces information & data for order processing, production routing & production control. Data collection provides production progress information and actual job cost. On completion all records are archived for historical reference if needed. The system is seamlessly integrated with the company's accountancy system.

The system is 'off-site' backed up & supported. Customers can be assured that all records & information would be instantly restorable in the event of system failure.

CadCam

The company utilizes BobCad as the preferred support system. They have the 'Wire Eroding, 3D Milling & 5 Axis Machining packages. Machine operators are responsible for producing their own programs by either utilizing the Cam software or MDI programming at the machine on Fanuc, Hurco Ultimax & Hurco Winmax control systems.

Turning

In addition to CNC chucking & barfeed machines, the section also encompasses several manual machines for low volumes & secondary operations.

Milling

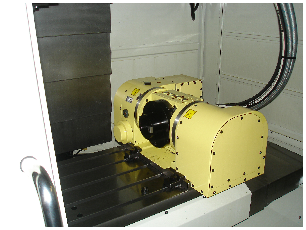

The milling section has nine machining centres offering 3, 4 & 5 axis capability The Company's machine of choice is Hurco as a result of their industry specific software & conversational programming control. Several manual machines supplement the section.

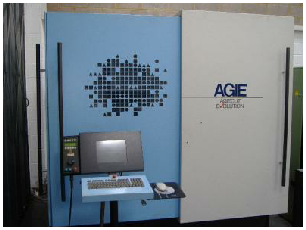

Wire Eroding

Agiecut Evolution 2 CNC WEDM

Spark eroding

Charmilles Form 2-LC

Eurospark ES 750 (With 'X Box Attachment' polarity for the eroding

of tungsten based materials)

Surface Grinding

5 Jones & Shipman 540L Jones & Shipman 1400

Cylindrical Grinding

Extensive universal grinding capacity

Inspection Facilities

Extensive facility including Elbo inspection presetter with Sony camera, Sigma 750 projector, appropriate gauges & checking equipment

Balancing capability

Hoffman tool balance simulator

Chemical Blacking

Hot & cold process

Obsolete Product Manufacture

End users are often faced with the problems of re-tooling old machines or manufacturing products from a bygone era. CSN provide a valuable service for major international cutting tool companies, machine suppliers, agents, distributors & end users by providing a manufacturing source for obsolete standard products or items which can no longer be procured from OEM sources which are no longer operating.

There is a national & international requirement for the supply of equipment that is no longer readily available from the original source. CSN have the capability to provide a solution to this problem by being able to produce from fully detailed drawings or reverse engineer from provided samples. It is the combination of being former employees of one of the world's leading special tool manufacturers & a manufacturing source for major international tooling suppliers for the last 30years.

The 'Selling On' of obsolete production lines to developing countries means that there is also need for a manufacturing source that is familiar with modern & old methodology, technology, machines & machining techniques. CSN has provided that source for several such projects on an international basis both for third party sources & directly to for the new manufacturer.

Such projects include major automotive engine production lines being relocated to the middle & Far East.

Reverse Engineering

Customers regularly request manufacture of products whereby they have a sample but no drawing. CSN have the capability to analyze, measure, draw & reproduce to an exacting standard. Such products as basic boring tools, milling cutters, feed-out tools and auto-adjust hones have all been produced from a simple request of 'Can you make this, I'm sorry I don't have a drawing'.

| Toolholders, Cartridges & Threading Tools |

| Milling Cutters |

| Boring Bars |

| Line Boring Bars |

| Feedout and Motion Tools |

| Milling Arbors |

| General Machining |

| Workshop Equipment |

| Toolholders, Cartridges & Threading Tools |

| Milling Cutters |

| Boring Bars |

| Line Boring Bars |

| Feedout and Motion Tools |

| Milling Arbors |

| General Machining |

| Workshop Equipment |